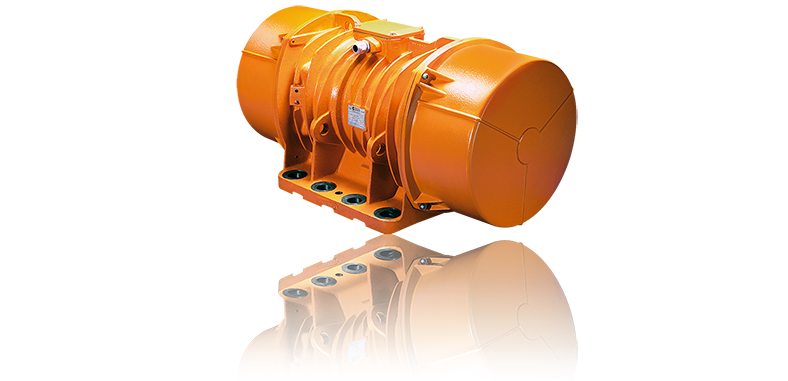

| MVSI Electric vibrators |

|

3000/3600 RPM |  |

|

1500/1800 RPM | ||

|

1000/1200 RPM | ||

|

750/900 RPM | ||

|

MVSI serisi piyasadaki en geniş ürün yelpazesine sahiptir. Yüksek teknoloji, çok yönlülük, güvenilirlik, sağlamlık, uzun rulman ömrü ve uzun ömürlü yağlama MVSI serisinin bazı önemli özelliklerindendir. Eleme, kalibrasyon, seperasyon, sıkıştırma, taşıma, kurutma, besleme, boşaltma, yıkama işlemlerinde ve daha birçok uygulamada yaygın olarak kullanılmaktadır. ATEX sertifikasına sahip olan MVSI serisi Zone 21 ve 22 ortamında çalıştırmaya uygundur. |

|||

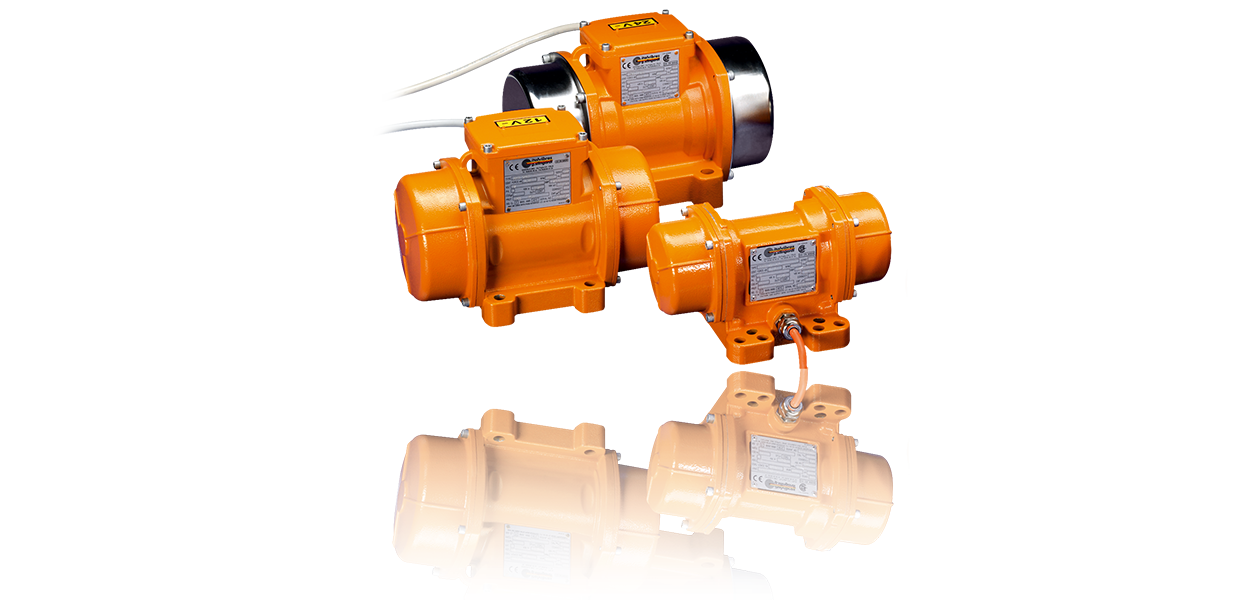

| MVSI-TS Electric vibrators with split covers |

|

1500/1800 RPM |  |

|

1000/1200 RPM | ||

|

750/900 RPM | ||

|

MVSI-TS serisi MVSI serisinin yan kapakları parçalı olan modelidir. Ağırlık kapağı iki parçaya bölünmüş olup, radyal yönde ayrılabilecek şekilde tasarlanmıştır. Tasarım ve gereklilikler doğrulutusunda bir kapağın veya her iki kapağın da parçalı imal edilmesi mümkündür. MVSI-TS serisi ağırlık kapaklarının eksenel olarak çıkartılamayacağı pozisyonlarda monte edilmesi durumunda zaruridir. MVSI-TS serisi, uluslararası IEC ve EN standartlarına haiz olup, patlayıcı toz ihtiva eden ortamlarda çalışmaya uygundur. |

|||

| MVSI-E Increased safety electric vibrators |

|

3000/3600 RPM |  |

|

1500/1800 RPM | ||

|

1000/1200 RPM | ||

|

750/900 RPM | ||

|

MVSI-E serisi, ATEX Direktifine (94/9/EC) uygun olarak, patlayıcı gaz ve toz varlığı nedeniyle potansiyel olarak patlayıcı atmosfere sahip ortamlardaki endüstriyel proseslerde kullanılmak üzere tasarlanmıştır. MVSI-E serisi özellikle zone 1. ve 2. (gaz) ve zone 21. ve 22. (tozlar) kullanılabilir. |

|||

| MVSS Electric vibrators in stainless steel |

|

3000/3600 RPM |  |

|

1500/1800 RPM | ||

|

1000/1200 RPM | ||

|

750/900 RPM | ||

|

MVSS serisi paslanmaz vibratörler Italvibras’ın sektördeki 40 yıllık tecrübesinin bir ürünüdür ve piyasa için önemli bir yeniliktir. Korozyona ve agresif maddelere karşı çok yüksek dirence sahip olmasından dolayı özellikle gıda, kimya, ilaç ve benzeri sektörlerde tercih edilmektedir. |

|||

| CDX Explosion-proof electric vibrators |

|

3000/3600 RPM |  |

|

1500/1800 RPM | ||

|

1000/1200 RPM | ||

|

750/900 RPM | ||

|

CDX patlamaya dayanıklı vibratörler, potansiyel olarak patlayıcı bir atmosferdeki endüstriyel proseslerde kullanılmak üzere tasarlanmıştır. CDX vibratörlerin muhafazası, dahili bir patlamanın çevreye iletilmesini önlemek için artırılmış kalınlık ve bağlantılarla donatılmıştır. CDX serisi, vibratör modeline bağlı olarak birçok farklı sertifika ile karakterize edilir ve geliştirilir. |

|||

| MVT, MVTX Explosion-proof screen electric vibrators |

|

1500/1800 RPM |  |

|

MVT, MVTX patlamaya dayanıklı elek vibratörleri, potansiyel olarak patlayıcı bir atmosferdeki endüstriyel proseslerde kullanılmak üzere tasarlanmıştır. Geniş eleklerde endüstriyel eleme işlemleri için kullanılırlar. Bu elek vibratörlerinin muhafazası, dahili bir patlamanın çevreye iletilmesini önlemek için artırılmış kalınlık ve bağlantılarla donatılmıştır. Patlamaya dayanıklı elek vibratörleri UL, cUL, ATEX ve IECEx işaretlerini taşır. |

|||

| MICRO Electric vibrators with reduced overall size |

|

3000/3600 RPM |  |

|

MICRO serisi, küçük merkezkaç kuvveti ve küçük boyutların gerekli olduğu proseslerde sürekli endüstriyel hizmet için tasarlanmıştır. MICRO vibratörler, kimya endüstrisi, gıda endüstrisi, ilaç, paketleme ve genel olarak otomasyonda kullanılan otomatik makinelerde besleme, taşıma, eleme, boyutlandırma, ayırma işlemleri, sıkıştırma gibi çok sayıda uygulamada kullanılır. |

|||

| M3 Multi-hole fixing electric vibrator |

|

3000/3600 RPM |  |

|

1500/1800 RPM | ||

|

Sürekli çalışma için tasarlanan M3 serisi, kompakt bir şekle, küçültülmğş genel boyutlara ve alt tarafında terminal kutusuna sahiptir. Çok delikli montaj ayakları M3 serisinin mevcut birçok montaj plakasıyla eşleşmesini sağlar. M3 serisi motorlar en son uluslararası standartlara uygundur. Patlayıcı tozlu ortamlarda özellikler zone 21 ve 22 de kullanılabilir. |

|||

| M3-E Increased safety multi-hole fixing electric vibrator |

|

3000/3600 RPM |  |

|

M3-E modeli, ATEX Direktifine (94/9/EC) uygun olarak potansiyel olarak patlayıcı gaz ve toz ortamlarındaki endüstriyel proseslerde kullanılmak üzere tasarlanmıştır. M3E özellikle zone 1 ve 2 (gaz) ile zone 21 ve 22 de (toz) kullanılabilir. |

|||

| MVCC Direct current electric vibrators |

|

Technical Details |

|

|

Doğru akımlı vibratörü olan MVCC serisi, şebeke elektriğinin bulunmadığı durumlarda kullanılmak üzere özellikle bunkerler, silolar ve kapı kontrolleri ve tekerlekli araçlar için (beton mikserleri, beton pompaları, sıvacılar, tuz dağıtıcıları, çakıl serpici, gübre serpici, çekilen silolar, endüstriyel süpürge filtreleri) tasarlanmıştır. MF modelleri, farklı delik merkezi mesafelerine uyum sağlamak için çok delikli bir sabitleme tabanına sahiptir. |

|||